Diecasting Malaysia has seen substantial growth in the last several decades, and has established itself as an integral part of Malaysia’s manufacturing industry. The highly-specialized process involves the injection of molten metal into steel molds in order to produce precise and high-quality parts. Diecasting’s growth in Malaysia is due to its strategic emphasis on the development of technology, industrialization and an emphasis on the highest quality. In the process of Malaysia is expanding its manufacturing base, diecasting is a key element in supporting numerous sectors such as electronics, automobiles and consumer products which contribute to Malaysia’s development and competitiveness globally.

The basis of Malaysia’s diecasting industry is founded on government policies that aim to encourage the development of industries and diversifying economics. initiatives like that of Malaysian Investment Development Authority (MIDA) as well as the National Policy on Industry 4.0 has attracted significant foreign investment as well as facilitated technological advances. The policies created an environment favorable for industrial development, which has allowed local and multinational businesses to prosper. The creation of industrial zones equipped with the latest technology has also helped cement Malaysia’s standing as the preferred location for diecasting as well as other manufacturing operations. The strategic emphasis on building an industrial ecosystem that is robust is a key factor in the rapid growth of the industry.

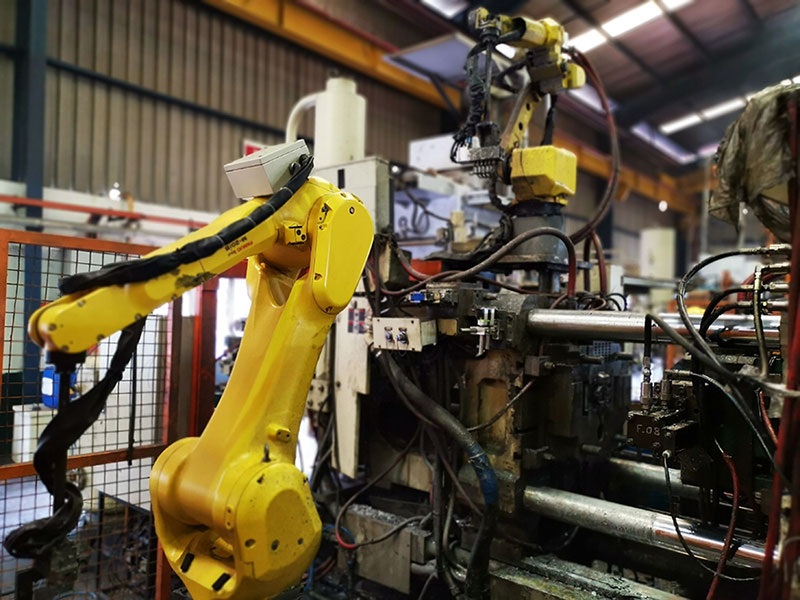

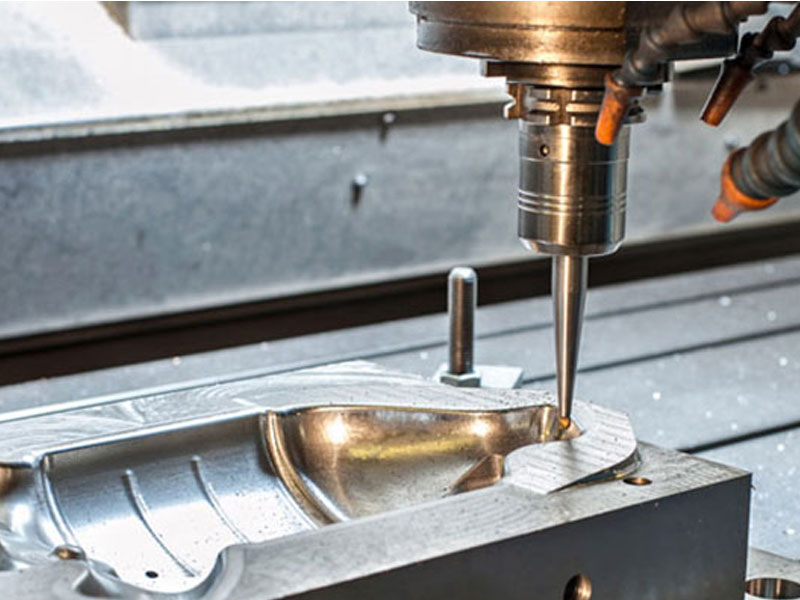

Technology innovation is an essential factor in the business’s progress in Malaysia. Modern manufacturing techniques, like computers-aided design (CAD) as well as computer-aided manufacturing (CAM) is revolutionizing the process of diecasting. The CAD and CAM technologies enable the production of intricate and precise parts with a low defects and high efficiency. Robotics and automation also have contributed significantly to improving productivity and consistency diecasting processes. Monitoring systems that are real-time and provide data analytics help manufacturers optimize manufacturing processes, cut down on production waste and maintain the same high-quality. Continued investing into R&D (R&D) guarantees that Malaysian diecasting industry stays on the forefront of technological advances, while maintaining its position as a leader in the international market.

Sustainability is becoming more and more important in the Malaysian diecasting business. In a world where demand for ecologically sustainable manufacturing methods increases, Malaysian diecasters are adopting environmentally friendly processes and products. They are using recycled metals, employing energy-efficient methods of production, and adherence to the strictest environmental standards. Its dedication to sustainability is evident by the quest for international certifications, as well as the conformity with international environmental standards. With a focus on environmentally friendly manufacturing methods The Malaysian diecasting business not only is able to meet the changing demands of its global clients, as well as contributes to larger efforts to reduce environmental impacts. For more information please visit here https://www.senadiecasting.com.my/

Development of human capital is another important factor that drives the development of the diecasting business in Malaysia. An educated and skilled workforce is vital to maintain top quality standards and encouraging innovation. Malaysian schools and vocational training facilities work closely with industry professionals to offer special training programmes that meet specific requirements for diecasting. They ensure that the workers have the most up-to-date technology and skills needed to work with the latest manufacturing technology. Professional development initiatives continue to improve the skills of employees, encouraging an environment of constant development and excellence. A focus on developing human capital is a sign of that the company’s determination to keep an efficient and competitive manufacturing industry.

Diecasting in Malaysia has become an essential element of the nation’s manufacturing and is driven by government strategic initiatives, technological innovations sustainable efforts, as well as growth in human capital. Its rapid growth has established Malaysia as a major participant in the worldwide market for diecasting, supporting various sectors as well as contributing greatly in the country’s development economic. In the years ahead, as Malaysia expands its capabilities in the field and adopt cutting-edge technologies, the sector is set to continue its development and greater success. By advancing its capabilities and fostering collaborative efforts, it continues to play an integral influence on Malaysia’s industrial future, and ensure that it stays at the cutting edge in precision manufacturing globally.

Leave a Reply