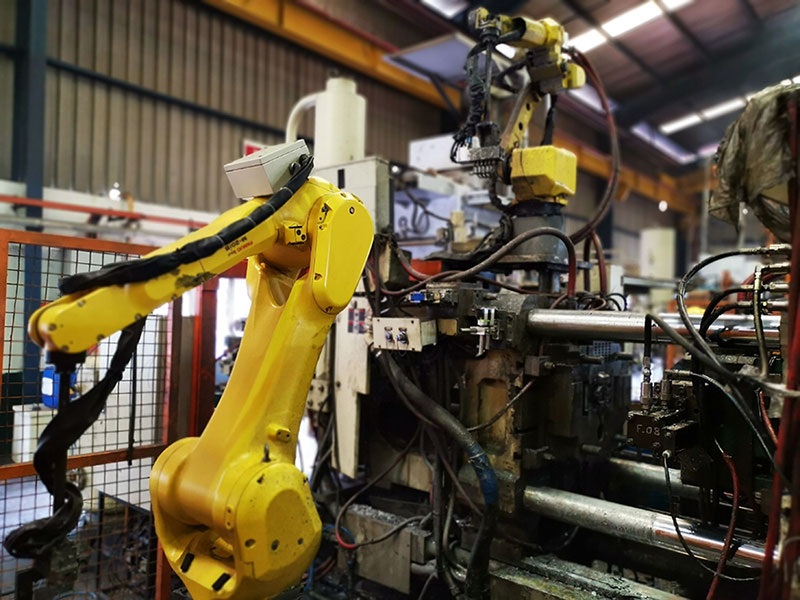

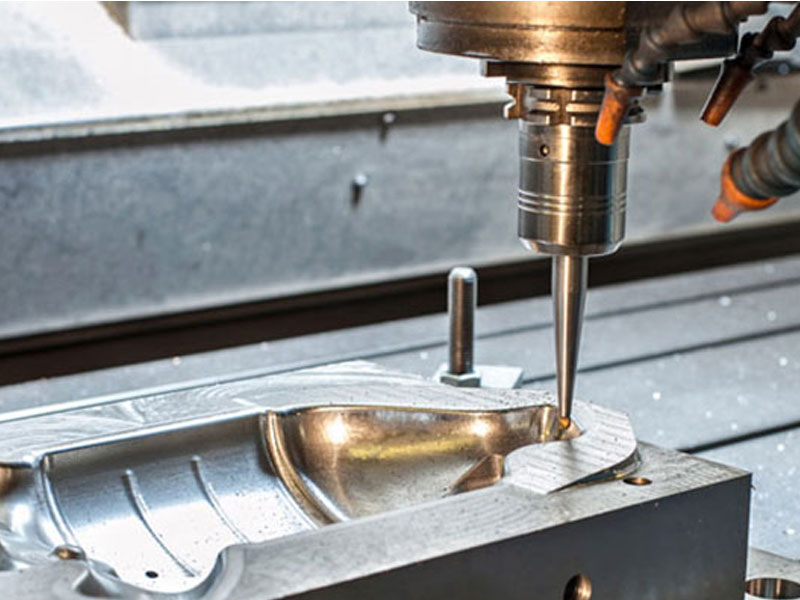

Die casting is a vital manufacturing technique which plays an important part in Malaysia’s manufacturing landscape. The process is known for its efficacy and capability to create intricate metal components with high precision and precision, it has been the foundation of many sectors in Malaysia which include automotive, electronics as well as consumer goods. Die casting involves the injection of the molten metal in a die or mold under extreme pressure in order to create products with a smooth with a perfect finish, and extremely tight tolerances. Malaysia is a strategic geographical location, and a growing industry is now a major hub for companies in die casting serving both local and international market. The latest manufacturing technology has transformed the method by which metal components are manufactured and offers cost-effective solutions for massive production.

One of the main reasons for the rapid growth of the die-casting industry within Malaysia is the rising demand for automotive components. Automotive manufacturers need high-end, light and robust metal components for their vehicles. And die casting provides the best solution. With this technique, pieces like engine blocks, transmission cases, as well as structural parts can be made quickly and precisely. The proximity of Malaysia to major automobile markets across Southeast Asia makes it an perfect location for die-casting businesses to flourish. Furthermore, the growth of the electric car (EV) production increased the need for components made of die-cast, since they rely heavily on aluminum components to decrease the weight of their vehicles and increase efficiency in energy use. For more information please visit here Senadiecasting

The electronic sector that is present in Malaysia is a further major force that is driving demand for casting dies. Malaysia has been for a long time an international hub for electronic production, and die casting is vital roles in making precise components that are used in every aspect of smartphones and home appliances. Die casting’s ability to make intricate and small-scale components with precise tolerances makes it essential to electronics in which precision is essential. In addition, the increasing tendency to reduce the size of electronics has resulted in a growing demand for more precise die-cast parts. Malaysian die-casting companies have the capacity to tackle these demands, and offer new solutions to meet changing demands of electronics industry.

Innovation and sustainability are becoming more and more important in the casting business, and Malaysia isn’t an the only one. With environmental issues growing the majority of die casting firms within the country are adopting eco-friendly practices to lessen the carbon footprint of their operations. Recycling of material, production techniques that are energy efficient and techniques for reducing waste have become more prevalent in the business. In addition, improvements in casting techniques, like using coolers that are more efficient and enhanced mold designs can boost productivity as well as reducing environmental impacts. Die casting in Malaysia contributes to the growth of its industrial sector and advancing global attempts to create sustainable manufacturing.

Die casting industry in Malaysia benefit from a well-trained workforce as well as an advanced infrastructure which supports the growth of the industry. The Malaysian government has been active in supporting industrial growth with initiatives including tax incentives, development of infrastructure as well as partnerships with international corporations. These initiatives have allowed local die casting firms to purchase state-of-the-art equipment and techniques, establishing Malaysia as an industry leader on the international die casting industry. Furthermore, Malaysia’s emphasis on technical and educational training has resulted in the workforce with a solid understanding of advanced manufacturing processes which has further contributed to the development of the business.

In the end the die casting industry is a key component of Malaysia’s economic environment, and plays a crucial part in industries such as electronic, automotive and consumer products. Its location in the middle of Asia as well as the growing demand for lightweight and high-precision components, and dedication to sustainable development and innovation makes it an ideal hub for die casting processes. With the demand worldwide for premium metal parts is increasing and the die-casting industry in Malaysia is ideally placed to satisfy this demand with modern manufacturing methods as well as a highly skilled workforce. In the future, the business is expected to continue its evolution by embracing the latest technologies and environmentally sustainable methods to keep its position as a leader in the world market.

Leave a Reply